When the working fluid is a gas that is compressed and expanded but doesn't change phase , the refrigeration cycle is called a gas cycle. Air is most often this working fluid. As there is no condensation and evaporation intended in a gas cycle , components corresponding to the condenser and evaporator in a vapor compression cycle are the hot and cold gas gas-to-gas heat exchangers in gas cycles.

The gas cycle is less efficient than the vapor compression cycle because the gas gas cycle works on the reverse Brayton cycle instead of the reverse Rankine cycle. As such the working fluid does not receive and reject heat at constant temperature. In the gas cycle , the refrigeration effect is equal to the product of the specific heat of the gas and the rise in temperature of the gas in the low temperature side. Therefore , for the same cooling load , a gas refrigeration cycle needs a large mass flow rate and is bulky.

Because of their lower efficiency and larger bulk , air cycle coolers are not often used nowadays in terrestrial cooling devices. However , the air cycle machine is very common on gas turbine-powered jet air craft as cooling and ventilation units , because compressed air is readily available from the engines' compressor sections. Such units also serve the purpose of pressurizing the aircraft.

Friday, November 11, 2011

Tuesday, September 13, 2011

Vapor absorption cycle

In the early years of the twentieth century , the vapor absorption cycle using water-ammonia systems was popular and widely used. After the development of the vapor compression cycle , the vapor absorption cycle lost much of its importance because of its low coefficient of performance (about one fifth of that of the vapor compression cycle). Today the vapor absorption cycle is used mainly where fuel for heating is available but electricity is not , such as in recreational vehicles that carry LP gas. It is also used in industrial environments where plentiful waste heat overcomes its inefficiency.

The absorption cycle is similar to the compression cycle , except for the method of raising the pressure of the refrigerant vapor. In the absorption system , the compressor is replaced by an absorber which dissolves the refrigerant in a suitable liquid , a liquid pump which raises the pressure and a generator which , heat addition , drives off the refrigerant vapor from the high-pressure liquid. Some work is needed by the liquid pump but , for a given quantity of refrigerant , it is much smaller than needed by the compressor in the vapor compression cycle. In an absorption refrigerator , a suitable combination of refrigerant and absorbent is used. The most common combinations are ammonia (refrigerant) and water (absorbent) and water (refrigerant) and lithium bromide (absorbent).

The absorption cycle is similar to the compression cycle , except for the method of raising the pressure of the refrigerant vapor. In the absorption system , the compressor is replaced by an absorber which dissolves the refrigerant in a suitable liquid , a liquid pump which raises the pressure and a generator which , heat addition , drives off the refrigerant vapor from the high-pressure liquid. Some work is needed by the liquid pump but , for a given quantity of refrigerant , it is much smaller than needed by the compressor in the vapor compression cycle. In an absorption refrigerator , a suitable combination of refrigerant and absorbent is used. The most common combinations are ammonia (refrigerant) and water (absorbent) and water (refrigerant) and lithium bromide (absorbent).

Friday, June 3, 2011

Vapor - compression cycle

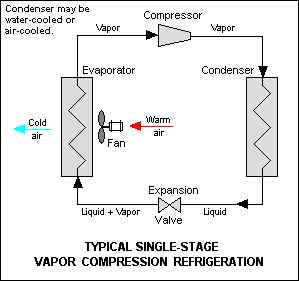

The vapor-compression cycle is used in most household refrigerators as well as in many large commercial and industrial refrigeration systems. Following picture provides a schematic diagram of the components of a typical vapor-compression refrigeration system.

The thermodynamics of the cycle can be analyzed on a diagram as shown follow. In this cycle , a circulating refrigerant such as Freon enters the compressor as a vapor. The vapor is compressed at constant entropy and exits the compressors superheated. The superheated vapor travel through the condenser which first cools and removes the superheat and then condenses the vapor into a liquid by removing additional heat at constant pressure and temperature. The liquid refrigerant goes through the expansion valve (also called a throttle valve) where its pressure abruptly decreases , causing flash evaporation and auto-refrigeration of , typically , less than half of the liquid.

That results in a mixture of liquid and vapor at a lower temperature and pressure. The cold liquid-vapor mixture then travels through the evaporator coil or tubes and is completely vaporized by cooling the warm air (from the space being refrigerated) being blown by a fan across the evaporator coil or tubes. The resulting refrigerant vapor returns to the compressor to the compressor inlet to complete the thermodynamic cycle.

The above discussion is based on the ideal vapor-compression refrigeration cycle and does not take into account real-world effects like frictional pressure drop in the system , slight thermodynamic irreversibility during the compression of the refrigerant vapor or non-ideal gas behavior (if any).

|

| Vapor compression refrigeration |

The thermodynamics of the cycle can be analyzed on a diagram as shown follow. In this cycle , a circulating refrigerant such as Freon enters the compressor as a vapor. The vapor is compressed at constant entropy and exits the compressors superheated. The superheated vapor travel through the condenser which first cools and removes the superheat and then condenses the vapor into a liquid by removing additional heat at constant pressure and temperature. The liquid refrigerant goes through the expansion valve (also called a throttle valve) where its pressure abruptly decreases , causing flash evaporation and auto-refrigeration of , typically , less than half of the liquid.

|

| Temperature–Entropy diagram |

That results in a mixture of liquid and vapor at a lower temperature and pressure. The cold liquid-vapor mixture then travels through the evaporator coil or tubes and is completely vaporized by cooling the warm air (from the space being refrigerated) being blown by a fan across the evaporator coil or tubes. The resulting refrigerant vapor returns to the compressor to the compressor inlet to complete the thermodynamic cycle.

The above discussion is based on the ideal vapor-compression refrigeration cycle and does not take into account real-world effects like frictional pressure drop in the system , slight thermodynamic irreversibility during the compression of the refrigerant vapor or non-ideal gas behavior (if any).

Thursday, April 7, 2011

Thermodynamic Cycle

According to the second law of thermodynamics heat cannot spontaneously flow from a colder location to a hotter area ; work is required to achieve this. Work is applied to cool a living space or storage volume by pumping heat from a lower temperature heat source into a higher temperature heat sink. The operating principles of the refrigeration cycle was described mathematically by sadi carnot in 1824 as a heat engine. A heat pump can be thought of as a heat engine which is operating in reverse.

Heat pump and refrigeration cycles can be classified as vapor compression , vapor absorption , gas cycle or stirling cycle types.

Heat pump and refrigeration cycles can be classified as vapor compression , vapor absorption , gas cycle or stirling cycle types.

Thursday, March 10, 2011

Heat pump and refrigeration cycle

Thermodynamic heat pump cycles or refrigeration cycles are the models for heat pumps and refrigerators. A heat pump is a machine or device that moves heat from one location (the 'source') at a lower temperature to another location (the 'sink' or 'heat sink') at a higher temperature using mechanical work or a high-temperature heat source. Thus a heat pump may be thought of a "heater" if the objectives is to warm an area , or a "refrigerator" if the objective is to cool an area ; regardless the operating principles are identical.

Wednesday, February 2, 2011

Refrigerants

Refrigerants

A modern R-134a refrigeration compressor

"Freon" is a trade name for a family of haloalkane refrigerants manufactured by Dupont and other companies. These refrigerants were commonly used due to their superior stability and safety properties. However , these chlorine-bearing refrigerants reach the upper atmosphere when they escape. Once the refrigerant reaches the stratosphere , UV radiation from the sun cleaves the chlorine-Carbon bond , Yielding a chlorine radical. These chlorine atoms catalyze the breakdown of ozone into diatomic oxygen , depleting the ozone layer that shields the Earth's surface from strong UV radiation. Each chlorine radical remains active as a catalyst unless it binds with another chlorine radical , forming a stable molecule and breaking the chain reaction. The use of CFC as a refrigerant was once common , being used in the refrigerants R-11 and R-12. In most countries the manufacture and use of CFCs has been banned or severely restricted due to concerns about ozone depletion. In light of these environmental concerns , beginning on November 14 , 1994 , the Environmental Protection Agency has restricted the sale , possession and use of refrigerant to only licensed technicians , per rules 608 and 609 of the EPA rules and regulations; failure to comply may result in criminal and civil sanctions. Newer and more environmentally-safe refrigerants such as HCFCs (R-22, used in most homes today) and HFCs (R-134a , used in most cars) have replaced most CFC use. HCFCs in turn are being phased out under the Montreal protocol and replaced by hydrofluorocarbons (HFCs) such as R-410A , which lack chlorine. Carbon dioxide (R-744) is being rapidly adopted as a refrigerant in Europe and Japan. R-744 is an effective refrigerant with a global warming potential of 1. It must use higher compression to produce an equivalent cooling effect.

Friday, January 7, 2011

Air conditioning system basic and theories - Humidity

Humidity

Air conditioning equipment usually reduces the humidity of the air processed by the system. The relatively cold (below the dew point) evaporator coil condenses water vapor from the processed air , much as cold drink will condense water on the outside of a glass. The water is drained , removing water vapor from the cooled space and thereby lowering its relative humidity. Since humans perspire to provide natural cooling by the evaporation of perspiration from the skin , drier air (up to a point) improves the comfort provided. The comfort air conditioner is designed to create a 40% to 60% relative humidity in the occupied space. In food retail establishments , large , open chiller cabinets act as highly effective dehumidifiers.

Some air conditioning units dry the air without cooling it. These work like a normal air conditioner , except that a heat exchanger is placed between the intake and exhaust. In combination with convection fans , they achieve a similar level of comfort as an air cooler in humid tropical climates , but only consume about one-third the energy. They are also preferred by those who find the draft created by air coolers uncomfortable.

Air conditioning equipment usually reduces the humidity of the air processed by the system. The relatively cold (below the dew point) evaporator coil condenses water vapor from the processed air , much as cold drink will condense water on the outside of a glass. The water is drained , removing water vapor from the cooled space and thereby lowering its relative humidity. Since humans perspire to provide natural cooling by the evaporation of perspiration from the skin , drier air (up to a point) improves the comfort provided. The comfort air conditioner is designed to create a 40% to 60% relative humidity in the occupied space. In food retail establishments , large , open chiller cabinets act as highly effective dehumidifiers.

Some air conditioning units dry the air without cooling it. These work like a normal air conditioner , except that a heat exchanger is placed between the intake and exhaust. In combination with convection fans , they achieve a similar level of comfort as an air cooler in humid tropical climates , but only consume about one-third the energy. They are also preferred by those who find the draft created by air coolers uncomfortable.

Subscribe to:

Comments (Atom)